When it comes to laser engraving, selecting the right equipment for your business is crucial. The right choice can significantly impact the quality, efficiency, and profitability of your engraving projects. To help you navigate this decision, we have prepared a comprehensive guide on choosing the right laser engraving equipment for your business. In this article, we will explore various factors to consider, with a particular focus on metal engravers. Let’s dive in and discover how to equip your business with the perfect tools for success.

Assessing Your Business Needs:

Before diving into the details of laser engraving equipment, it’s important to assess your business needs. Consider the types of materials you will be engraving, the desired engraving depth and precision, and the expected workload and production volume. By understanding these factors, you can narrow down your options and choose equipment that aligns with your specific requirements.

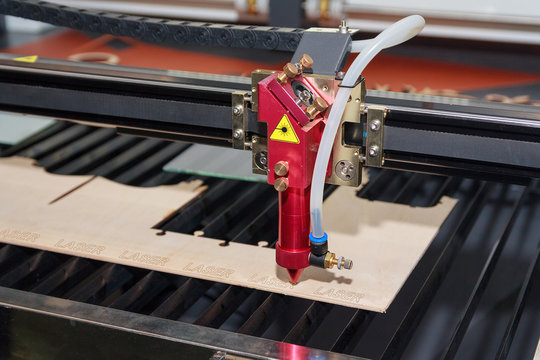

Understanding Laser Engraving Technologies:

There are three primary laser engraving technologies: CO2, fiber, and diode. CO2 laser engravers are versatile and suitable for engraving various materials, while fiber laser engravers excel in metal engraving. Diode lasers are typically used for low-power applications. Each technology has its pros and cons, and understanding them will help you make an informed decision based on your engraving needs.

Considerations for Metal Engravers:

Selecting laser engraving equipment specifically for metal engraving necessitates careful consideration, given the distinctive properties of metals. When evaluating options for a metal engraver, it is crucial to prioritize compatibility with various metal types, including stainless steel and aluminum. Additionally, it is essential to pay close attention to power and wattage specifications to ensure optimal engraving outcomes. Furthermore, pulse duration and frequency should be meticulously assessed, as they play a pivotal role in attaining the utmost precision and accuracy when engraving metals.

Evaluating Engraving Precision:

Engraving precision is a crucial aspect of laser engraving equipment. Consider spot size and focus capability, as smaller spot sizes allow for finer details in engravings. DPI (dots per inch) resolution plays a significant role in image quality, so ensure your chosen equipment provides high-resolution capabilities. Testing engraving results on various materials can give you a clear understanding of the precision offered by different models.

Assessing Ease of Use and Software Compatibility:

Ease of use and software compatibility are essential for maximizing productivity and efficiency. Look for equipment with a user-friendly interface and intuitive controls, reducing the learning curve for operators. Compatibility with popular design software such as Adobe Illustrator and CorelDRAW enables seamless integration into your existing workflow. Additionally, consider the availability of training resources and technical support to ensure a smooth transition.

Considering Maintenance and Longevity:

Maintenance and longevity are often overlooked aspects when choosing laser engraving equipment. Regular maintenance is necessary to keep the equipment in optimal condition. Consider the ease of routine maintenance and the availability of replacement parts. Investing in durable equipment with a long lifespan ensures that your engraving operations remain uninterrupted.

Cost Considerations:

While cost should not be the sole determining factor, it plays a significant role in the decision-making process. Evaluate the initial investment required for the equipment and allocate your budget accordingly. Additionally, consider the long-term operating costs, such as electricity and consumables. Calculating the return on investment (ROI) will help you determine the cost-effectiveness of the equipment in the long run.

Researching and Comparing Brands and Models:

Before making a final decision, conduct thorough research and compare different brands and models. Read reviews and testimonials from other users to gain insights into their experiences. Consulting industry experts and seeking advice from colleagues who have already invested in laser engraving equipment can provide valuable guidance. Requesting demos and test runs allows you to assess the performance and capabilities of the equipment firsthand.

Conclusion:

Choosing the right laser engraving equipment is crucial for the success of your business. By assessing your business needs, understanding different laser engraving technologies, considering specific requirements for metal engraving, evaluating engraving precision, and assessing ease of use, software compatibility, maintenance, and cost considerations, you can make an informed decision. Thorough research and comparison of brands and models will further refine your choice. By selecting the perfect laser engraving equipment, you equip your business for enhanced productivity, improved quality, and increased profitability. Invest wisely, and watch your business thrive in the world of laser engraving.